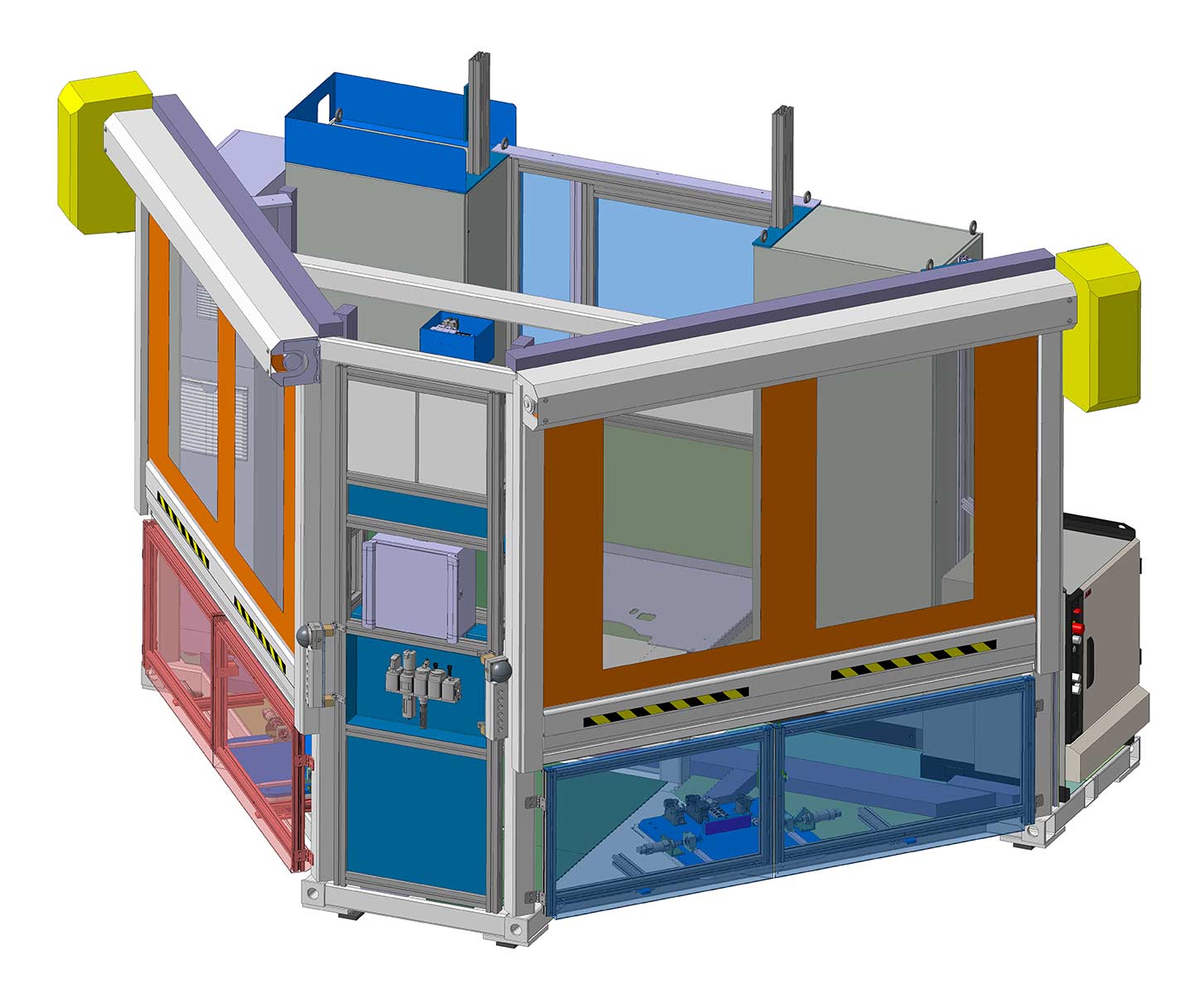

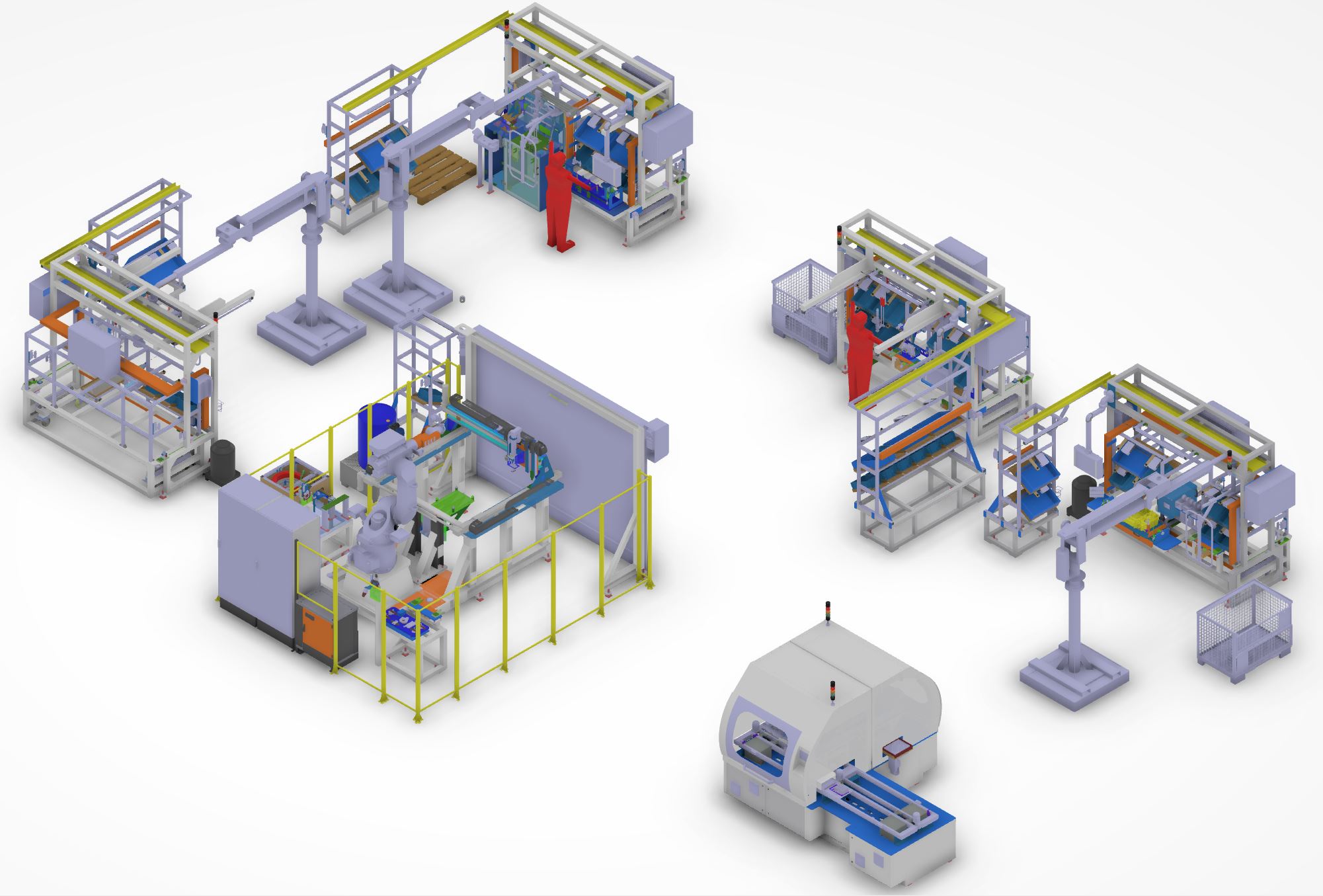

Palletizing or tray destacking systems are modules that enable automatic palletizing and depalletizing. These tray stackers simplify the logistics processes in automated production enormously. AKE technologies GmbH offers its concept as a standard product with its own control system.

The advantages of the AKE palletizing systems at a glance:

- Large storage capacity and fast changeover times

- Uninterrupted loading and unloading ensures smooth material flow

- Buffer systems allow high plant autonomy

- Space-saving design on a small footprint

- High flexibility due to individual design of tray sizes

- Optional camera systems for component position detection in the tray

- Hand scanner in the placement area and worker panels for visualization

Possible tray sizes of the AKE tray system:

- Width: 530-600 mm

- Depth: 350-400 mm

- Height: 25-200 mm

Are you looking for an efficient and flexible palletizing system?→ Feel free to contact us!

Our World of Automation | Learn more about our values and about the passion for our automation solutions in the team AKE!

Also learn more about other solutions::

Acoustic chamber

Acoustic test chambers enable the precise meas¬urement and evaluation of noise emissions or dis-ruptive noises by a combination of an outer noise enclosure and a sound absorbing lining on the in-side of the chamber.

Acoustic chambers consist of high-efficiency noise cancelling wall and ceiling panels, high-quality acoustic doors of customized dimensions, noise¬less LED lighting, inlet and outlet silencers, inte-grated cable ducts and soundproof cable passages.

The chambers can be equipped with wedge-type and planar absorbers that are designed, respec-tively, for semi-anechoic and highly sound-ab¬sorbing acoustic test chambers.

We partner with TS-tech, as they have the capacity to provide us with complete turn-key acoustic test chambers. We discovered that their chambers cre¬ate the environment our AKE systems need to per¬form disruptive noise tests with flawless results.

Climatic chamber

In the climatic chamber tests with a temperature range from -40°C to +80° are possible.

Its resistance to corrosion and environmental degradation make our shaker the system of choice for applications in climatic chambers. Our actuators are fit for continuous operation under any type of environmental conditions. Even if operated 24 hours a day, our High Power Shakers will retain their original condition along with their peak performance capability.

Boasting an exceptionally compact design, resulting in a remarkably small installation space, our shaker will pare down the operating costs of your climatic chamber as it shrinks down the space required for the chamber.

Another welcome benefit is that it helps keep the initial construction cost comparatively low. Thanks to our shakers’ resistance to climatic influences, there is no need to embed the actuators in the foundation.

Testing services at the S&R Lab

Feel free to use our service!

We have found that our customers benefit immensely from cooperating with AKE-technologies as a provider of measuring and testing services. In an effort to ensure that our services always garner our customers complete satisfaction we have set up a testing room at our location in Patriching: our Noise Analysis and Solution Centre.

Our Noise Analysis and Solution Centre is furnished with all products that are included in our NVH portfolio. All necessary equipment is available on site - from vehicle and components shakers to the noise recording system to the stick-slip testing bay.

Assisting you in analyzing and eliminating disruptive noises, our services will allow you to focus on the essential aspect of your business: selling your products.

Benefit from the experience of our specialists!

The use of innovative technologies for noise prevention is not an isolated individual discipline. To use them intelligently, they must be adapted to the specific application. This lets us provide our customers with high quality analyses, diagnostics and advice with the implementation.

We offer a series of workshops and training courses on the subject of disruptive noise acoustics which support you in selecting the best technology for your special requirements and in the ideal system integration.

Here are some sxamples of our workshops

- Disruptive noise treatment has to be planned: Introductory course with a complete assessment of your situation and strategy development for effective disruptive noise prevention

- Disruptive noise acoustics workshop: The Basics (one-day course)

- Disruptive noise acoustics workshop: Expert Course (two days)

- Disruptive noise analysis on the hardware

- Disruptive noise analysis in the development phase

- Stick-Slip measurement and assessment

- Shaker tests with corresponding drive files

The training sessions take place in our Squeak and Rattle lab or are also offered as in-house events.

With dynamic driving excitation, relative movements of two components can occur. The resulting transition from static to sliding friction is called a stick-slip effect. This is considered as the cause of the generation of creaking noise in the vehicle interior. These noises occur in places where, for example, parts of plastic, leather, rubber and glass come into contact with and rub against each other.

Vehicle acousticians are faced with the challenge of early detection of contact points in the development phase, which can cause the stick-slip effect. AKE-technologies offers a compact, portable stick-slip test bench that enables an objective evaluation of a wide range of material pairings. The test results meet the standards of the globally recognized VDA 230-206 or various car manufacturers.

System desciprion

Stick-Slip-Prüfstand / SSP04

- Small, compact and mobile test stand for analyzing material pairings in respect to their disruptive noise behavior

- Adjustable press-on force and travel speed

- Quick-change sample carrier

- Objective analysis of contact points by integrated sensor technology

The EvoCarb

The test bench for vehicle components - our EvoCarb - impresses with the completely redesigned optic and the technical performance increase through the swinging table made of carbon - which promises particularly effective Buzz Squeak and Rattle analyzes.

These unrivalled properties of the carbon material have an immediate positive effect on our new component shaker. Due to the low weight of the swing table of only 20 kg, components with a higher dead weight can be tested. The stiffness and the high load capacity of the carbon also cause a precise and extremely high power transmission in the component

Highly resistant to corrosion and environmental degradation in combination with shape retention in the event of temperature changes, the material used in our patented shaker makes the shaker perfectly suitable for use in a climatic chamber.

In spite of its singular capabilities, the EvoCarb is whisper quiet while in operation. Its negligible noise output makes it possible to pinpoint potentially disruptive noises and enables our customers to find the appropriate solutions at an early stage.

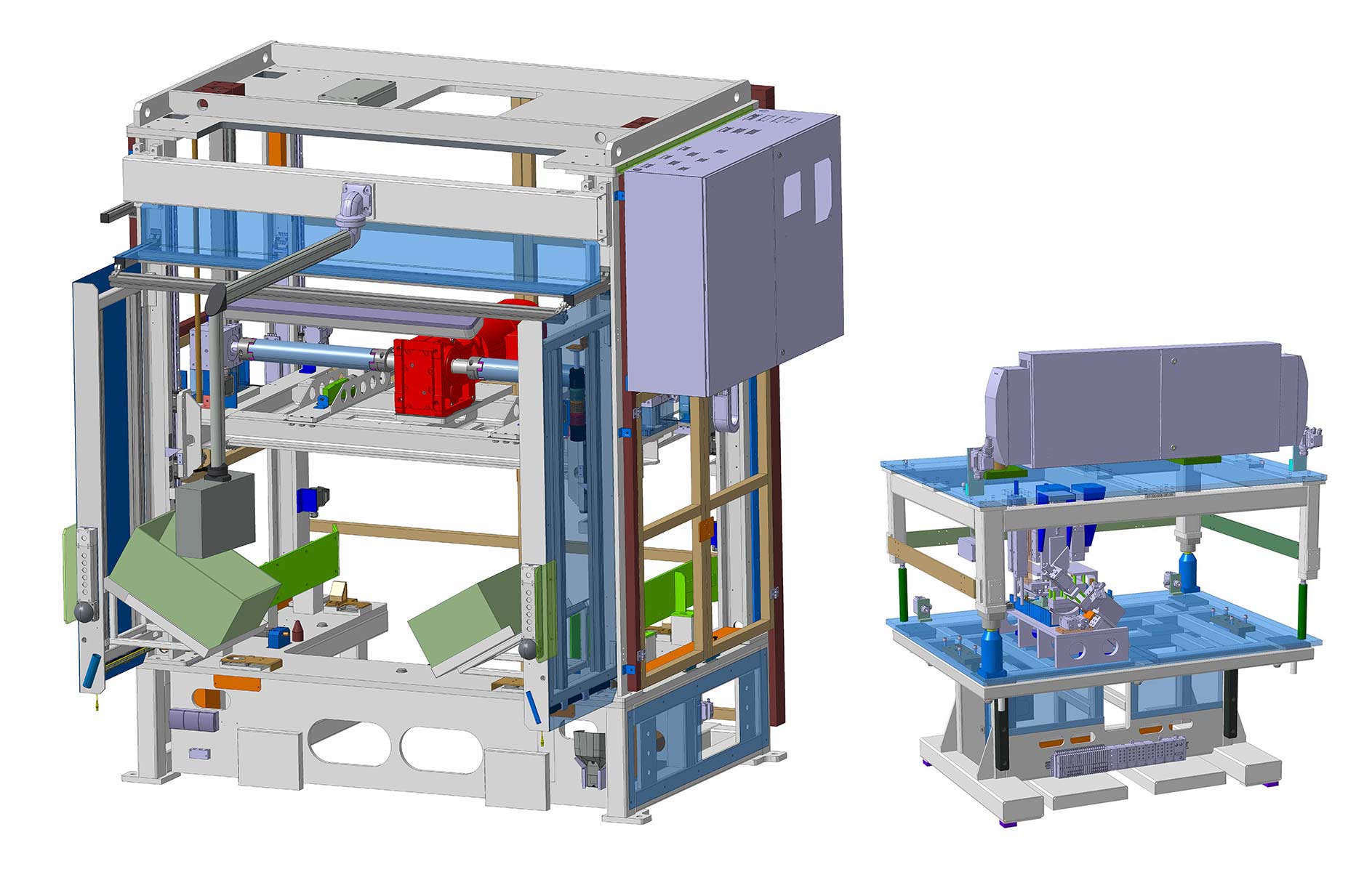

Shaker system for analyzing components

The components (e.g. seats and instrument panels) are consecutively or simulatneous excited on this shaker system in three axes (X/Y/Z) with time-history, random or synthetic signals. The simultaneous three-dimensional excitation with 3 actuators instead of just one promises an even more realistic simulation of roadway profiles.

System description

- Base frame with steel base plate and 3 adapter positions for a High Power Shaker

- Swivel table, 1500 x 650 mm, with component mount and bearings

- 1 or 3 HPS 350 High Power Shaker with adapter plate

- 11 kN excitation power per actuator in a compact and lightweight design

- 3 dimensional excitation is possible (3 axes at the same time)

- Switch cabinet with shaker controller

- PC system for control and analysis

- Sensor system and mounting device for drive file recording

- Software with data logger and sensor system for disruptive noise recording and analysis

By using our patented High Power Shaker in test bench construction for Squeak and Rattle analyzes, disturbing noises can be detected and eliminated in good time.

The use of accelerometers mounted on the bodywork via magnets means all movements of the vehicle can be recorded and, hence, a so-called 'Drive File' generated during a real test drive over the defined rough stretch of road. The use of HPS now makes it possible to induce the excitation recorded on the test track into the vehicle under laboratory conditions. The accuracy of the road profile simulation here is almost 100%. The advantage of the simulation is that there are no distracting secondary effects such as wind, engine or rolling noises. A further advantage is the exact reproducibility of the journey - as often as you like. This means all relevant disruptive noises can be detected and appropriate preventive measures taken in good time ahead of the start of series production.

Shaker system for the analysis of vehicles

The vehicles are agitated on this shaker system by two or four high power shakers in the vertical direction with time-history, random or synthetic signals. We recommend the variant with 4 actuators because the roadway simulations are even more realistic here.

System description

- Steel base plates as the basis of the system and for positioning the lifting systems and shakers

- Electric or Electro-hydraulic lifting system for positioning the vehicle

- 2 or4 HPS 350 high power shakers with electromagnetic locating and manual/hydraulic docking system

- 11 kN excitation power per actuator in a compact and lightweight design

- Actuator diameter 260 mm; Height 200 mm and only 30 kg weight

- Realistic noise analysis for vehicles up to 3.5 tons

- Switch cabinet with shaker controller

- PC system for control and analysis

- Sensor system and mounting device for drive file recording

- Software with data logger and sensor system for disruptive noise recording and analysis

Quality lies in quietness

Car drivers react extremely sensitively to distracting ambient noises in the interior. Noise design and elaborate vehicle acoustics with insignificant low values have become the norm today in all classes. Potential problem areas can be detected in good time and eliminated with the noise analysis from AKE-technologies.

Tremendous technological developments in the automobile and supply industry in recent years have resulted in the vehicle interior becoming ever quieter and therefore noises, that were obscured in earlier times, are increasingly perceived by customers as annoying. When new materials are employed, often it is not known beforehand what effect they have on the ambient noise in the interior. Even the interaction of certain materials can lead to unwelcome noises such as squeaking or creaking. In order to be ready for the consumer segment of the future, we provide our extensive range of services on the subject of noise acoustics.

AKE-technologies is the only company in the field of noise acoustics that provides the complete range of know-how and technology: From the excitation technology such as shaker systems to a solution in the form of anti-friction coating application systems. Our customers can benefit at an early stage from our know-how through theoretical support in the development phase.

With the German Noise Analysis and Solution Center (Störgeräuschanalyse- und Lösungszentrum or SALZ, we have created our own facility where we can graphically present the latest technologies and services in the field of disruptive noise acoustics to our customers.

We are your partner for Buzz, Squeak and Rattle themes!

For questions about the individual applications, please contact us via our

contact form!

for the treatment of arm rests, handles or trims

The edge folding machines from AKE consist of a press system and any number of exchangeable tools. All component-specific functions for processing the respective product are stored directly on the tool. As a result, each tool is functional in each press system without any programming effort.

The flexible systems that can be used at different locations are characterized by the output of almost 100% non-reworked components. Upon request, AKE also supports its customers in the design and layout of trim and energy directors.

system description

- Protection of workers by means of a light curtain with rear area protection

- part recognition systems for presence, position and, if necessary, color detection

- Machining of the components by various integrable processes: edge folding (Interior and exterior edge folding and processing of textile and Alcantara), mounting, punching, welding, riveting of attachments by means of hot rivets or ultrasound

- Ergonomic component removal from the upper tool

- Machining of various components by simple tool change

Our World of Automation | Learn more about our values and about the passion for our automation solutions in the team AKE!

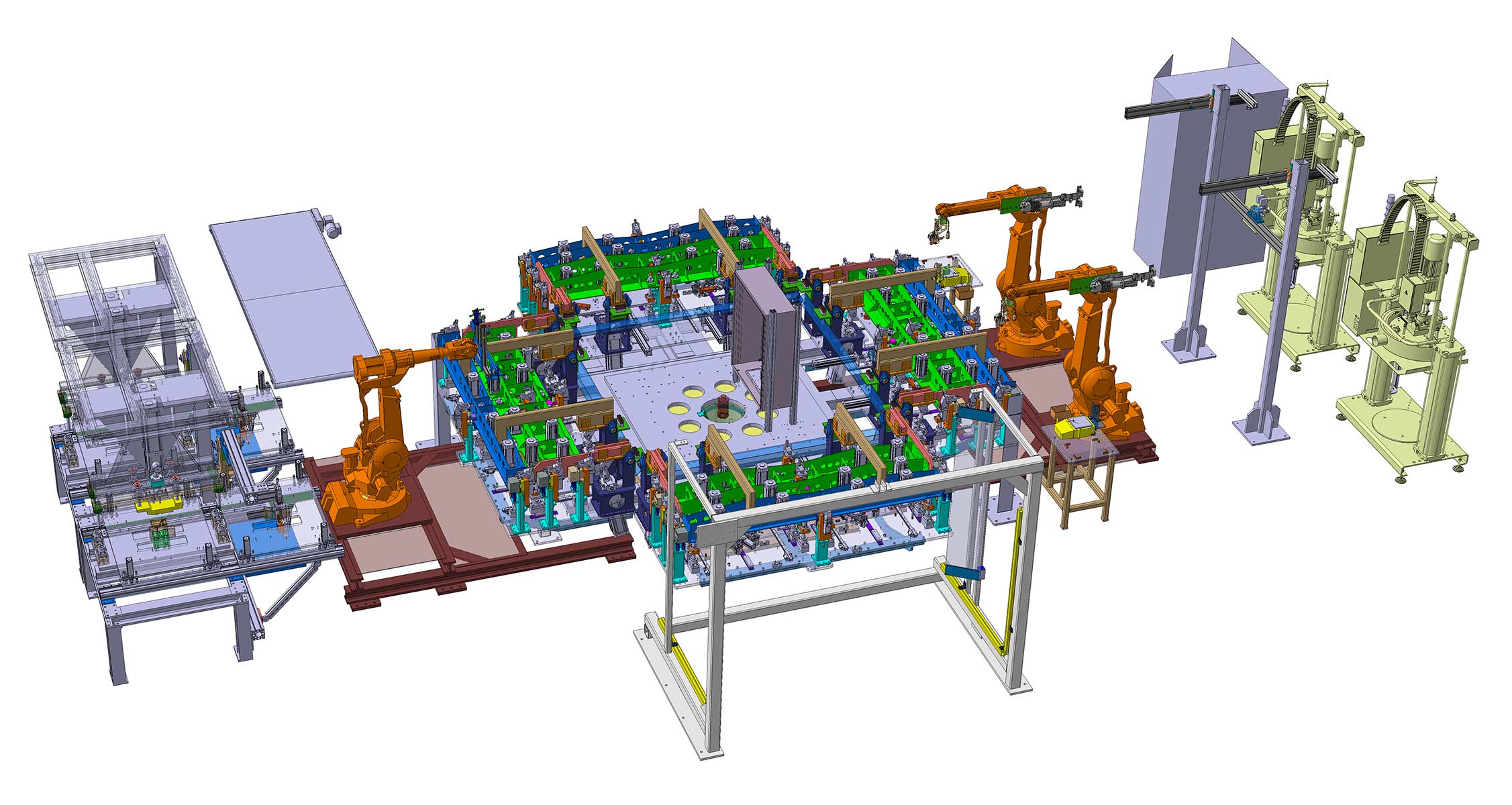

for the treatment of trims, armrests and seatbacks

As a technology-neutral manufacturer, we provide our customers with gluing and joining systems in all required degrees of automation. We combine many years of experience with power of innovation and absolute customer orientation. Newly developed processes are tested at AKE-technologies for their practical suitability in an extensive series of tests. The output is always a product with the highest level of quality.

Assembly-Laminating-Gluing System for the treatment and assembly of seat backs

System description

- System for fully automatic assembly of add-on parts on rear seat backrests and for sticking carpets on the seat back

- Inserting the metal structures and the backrest locks by the worker

- Automatic screwing of the backrest locks

- Automatic feeding and mounting of various bearing parts

- Picking up the carpets to be glued with robots from a magazine system

- Automatic insertion of carpets and metal structures into the rotary indexing table

- Apply glue to the carpets

- Heating and pressing of carpet and metal structure

- Automatic removal and component marking

- Documentation of all process data (torque and angle of rotation of screwing processes, carpet colors, temperature, amount of glue etc.)

- Automatic transport of all components during the entire assembly process

Gluing system for trim parts

System description

- System solution as rotary indexing table with four processing stations and parallel processing of two components to increase production capacity

- Workplace protection via contact-less light protection system with step-back guard for ergonomic workplace design

- Manual insertion of various components by the workers

- Tool systems with component mounting molds and bonding systems for attached components

- Component mounting molds with integrated parts detection and locating

- Automatic adhesive application with two robot systems applied as a bead for the downstream automatic jointing process

- Monitored jointing and cooling process of the glued joints

- Separate monitoring of the adhesive equipment with cyclical check of the output and tool alignment

- Automatic component removal with a robot system and transfer function to the downstream system for further processing

Our World of Automation | Learn more about our values and about the passion for our automation solutions in the team AKE!

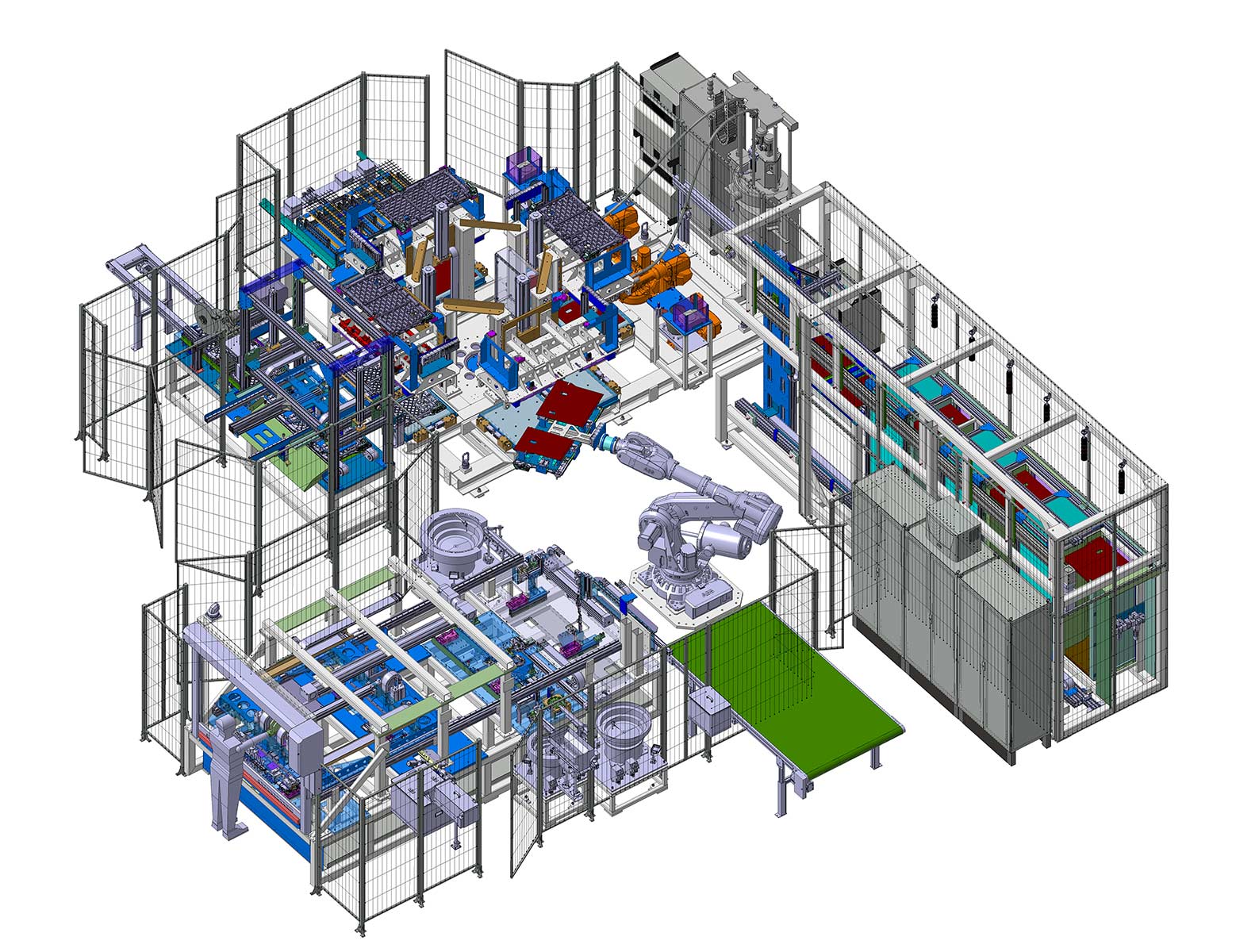

AKE technologies represents the system partner in the field of assembly of e-mobility components for its customers. We offer our customers experience in the development and manufacture of

assembly-testing lines for complete battery systems in various degrees of automation, from the prototype line to fully automated series production. We advise our customers on automation, manufacturing processes, security concepts and much more, always taking their individual requirements into account!

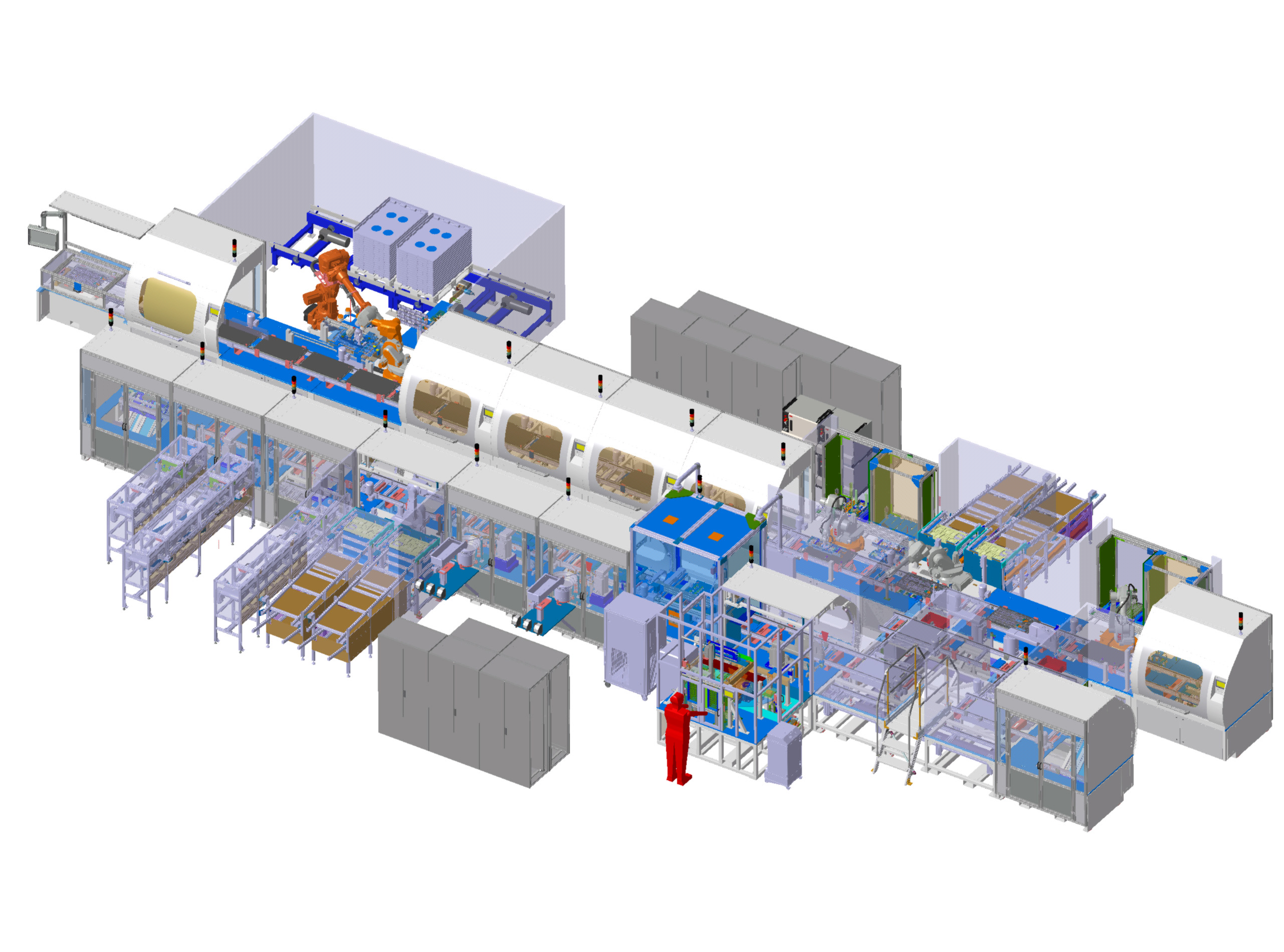

Pre-series line for the assembly of battery modules | Combination of manual and automatic processing stations

General Information

- Combination of manual and, if necessary, automatic processing stations

- Flexible design thanks to intelligent processing modules

- Integration of set-up carts and exchangeable processing modules

- Extension and reduction of the number of modules in the event of changes in the number of units

- Complete data documentation and process monitoring

Processes

- Automatic feeding and start of line tests of single cells and cell modules in different variants round cells, prismatic cells, pouch cells, modules with prismatic or pouch cells)

- Plasma or laser cleaning of battery cells and pre-treatment of application surfaces: plasma, flame, laser, liquid, ...

- Assembling of the cells with monitoring of mounting force and distance

- Application of adhesives and gap fillers including process control with camera and 3D scanning systems

- Laser welding of contacts with process monitoring

- Scope of assembly in the HV state of the battery in special HV cells (interconnection of modules, HV tests, covering of open contact points)

- Leakage test of the fully assembled system (air, helium, if necessary subsequent filling of the battery with a cooling medium)

- End of Line testing (communication test, plausibility test, high voltage test, functional test)

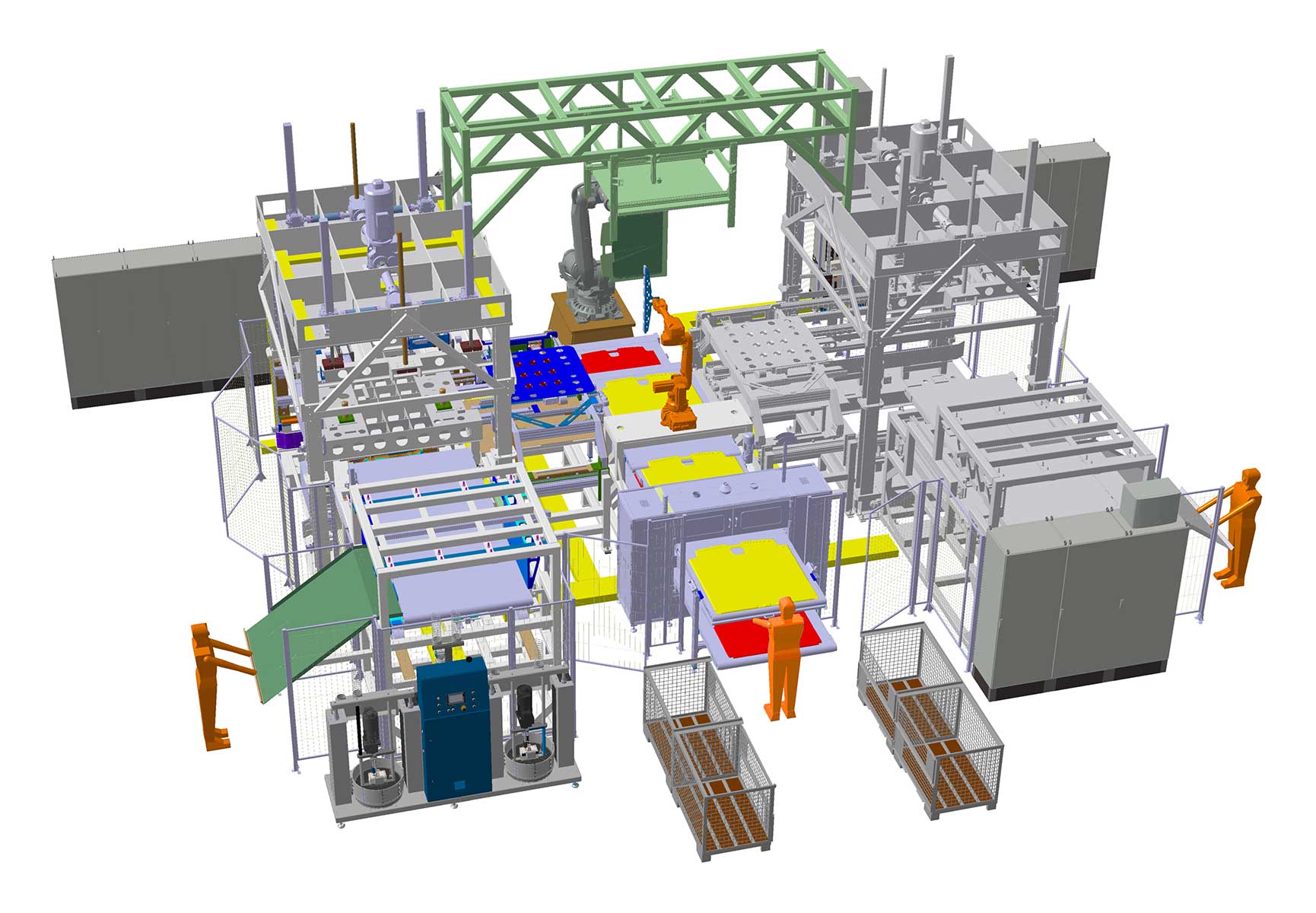

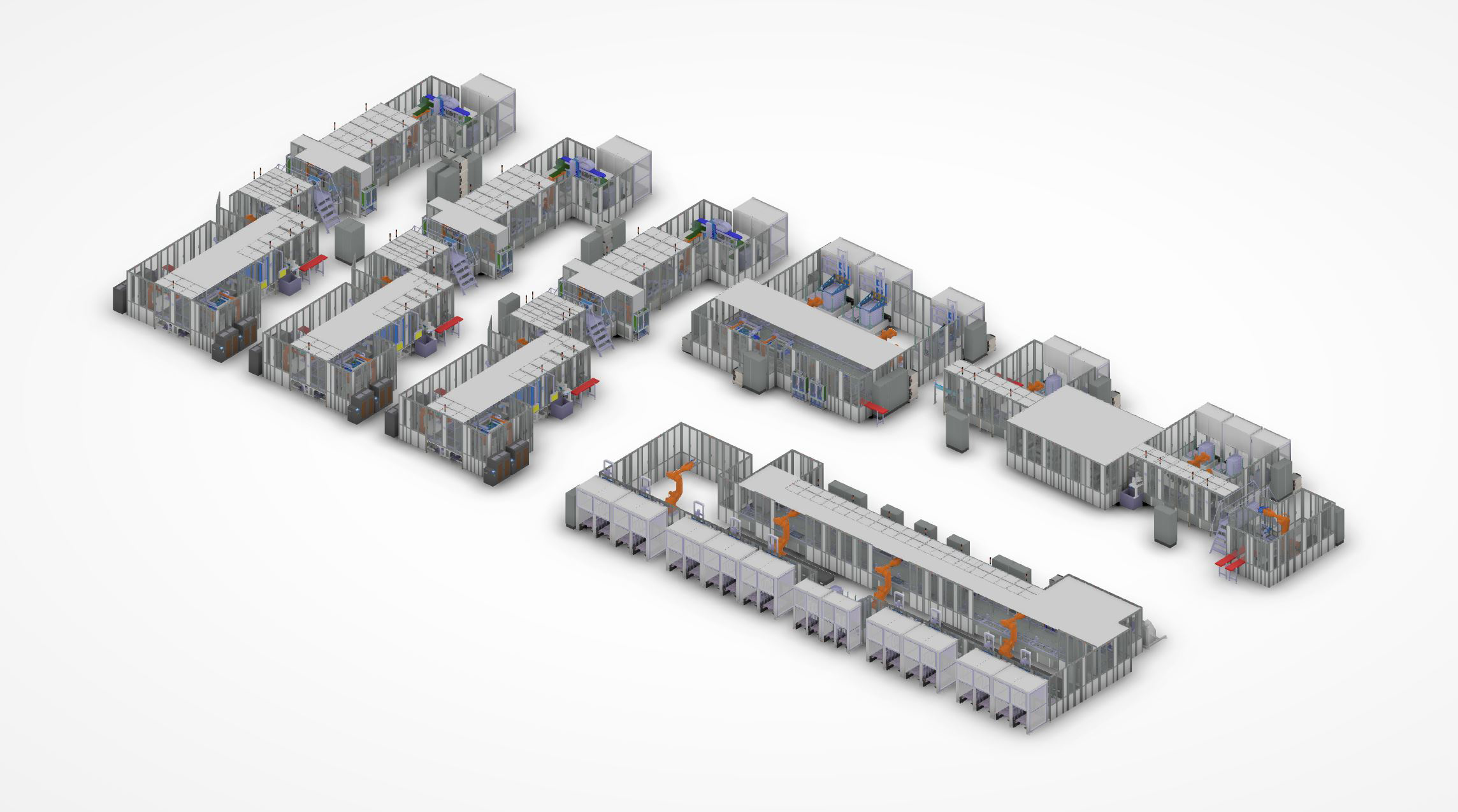

Automated assembly line for the production of battery modules from prismatic cells

General Information

- Processing of several cell variants on one line

- High demands on variant management

- Innovative transport systems for flexible plant design

- Combination of numerous individual processes in the smallest possible space

- Integrated emergency concepts in all process steps

- Process monitoring and data transfer to a higher-level production control system ensuring 100 percent traceability

Processes

- Begin of line testing to ensure processing of high quality components

- Cleaning and preparation processes on the cells, side and end plates (laser or plasma treatment, foil applications, camera inspections)

- Stacking & welding processes for battery assembly

- Pre-assembly and integration of the cell contacting system

- End of line testing (insulation and breakdown tests, cell temperature, voltage values)

- Component marking for traceability

- Automatic component output and packaging of modules

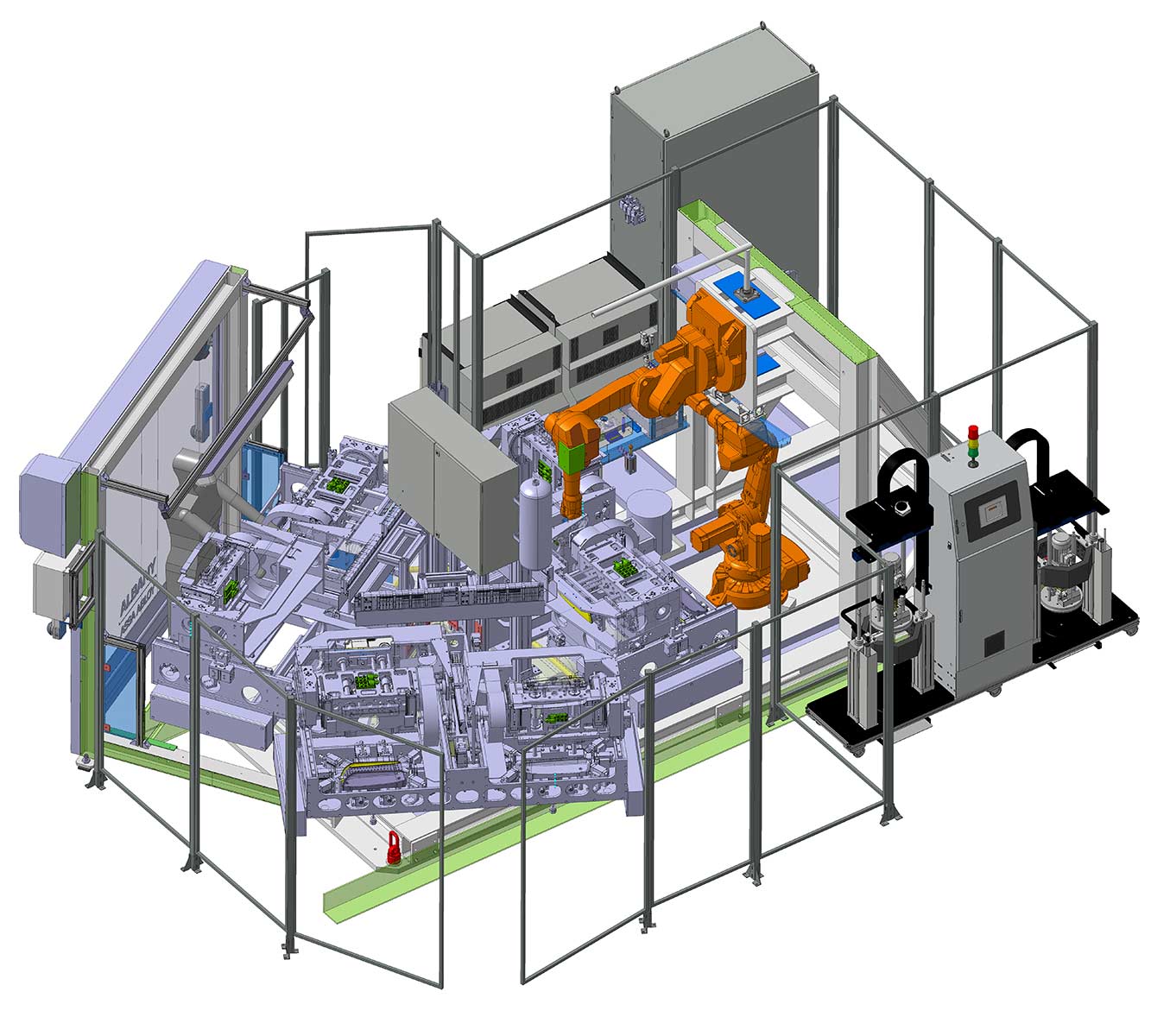

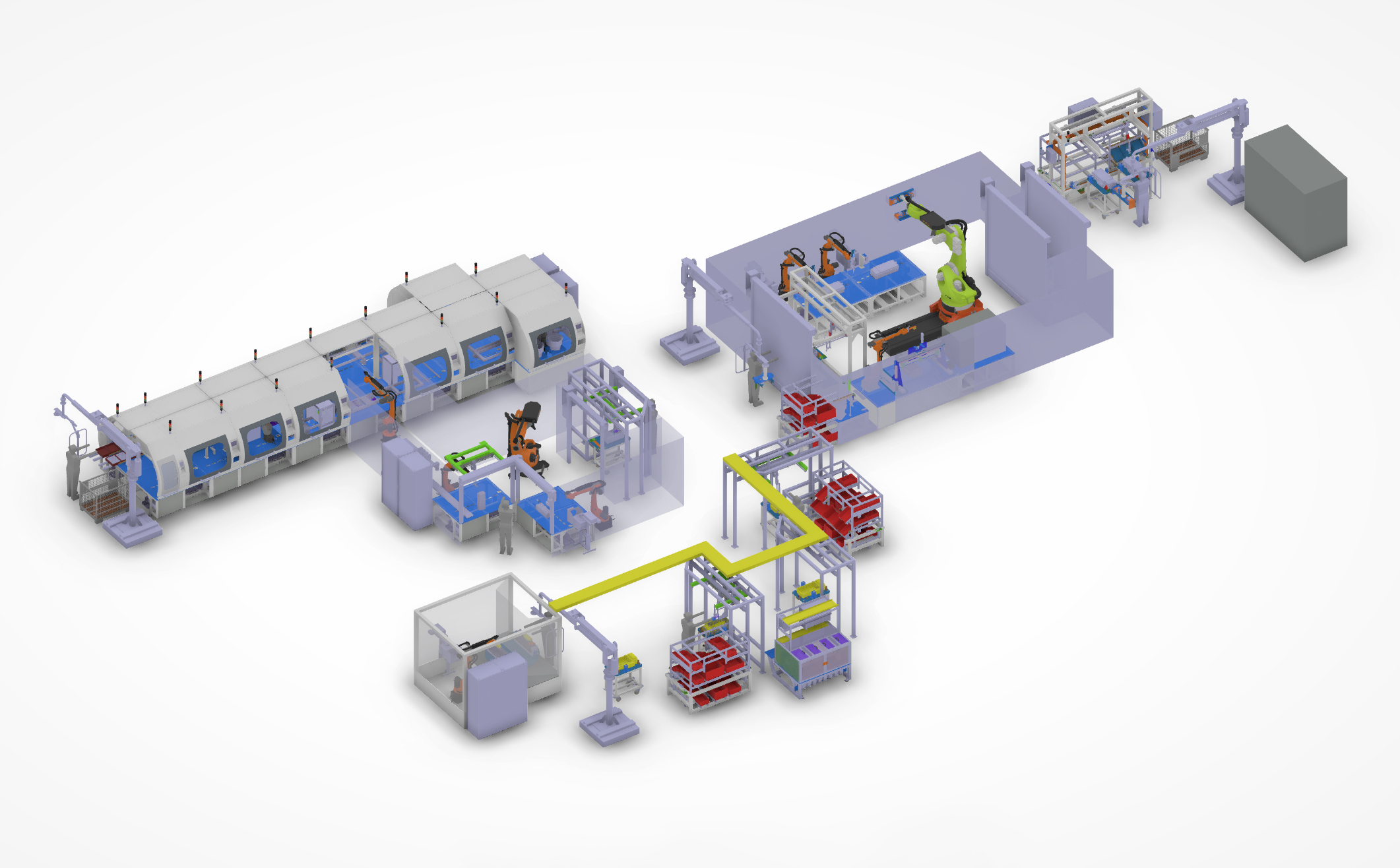

Assembly line for the production of battery modules and pack production from round cells

General Information

- Automated assembly processes with integration of manual processing steps

- Pre-production of different module variants

- Intermediate electrical testing

- Flexible pre-assembly of battery packs

- Automated final assembly area for inserting the battery modules and carrying out the HV activities

- Possibility for later integration of an automated transport system into the manual pre-assembly

- Complete data acquisition and process monitoring

Processes

- Automatic feeding and processing of single cells (cell scan, testing, cleaning)

- Assembly of single cells to battery modules (joining, laser welding, intermediate electrical testing)

- Partially automated pre-assembly of battery cases and lids (combination of manual assembly and automatic screwing stations)

- Automatic joining of modules into pre-assembled trays

- High-voltage interconnection of the battery system

- Lid assembly and leak test

- Intermediate and end of line electrical testing

- Manual component marking and packaging

Our World of Automation | Learn more about our values and about the passion for our automation solutions in the team AKE!

Learn also more about our further production lines in the field of e-mobility:

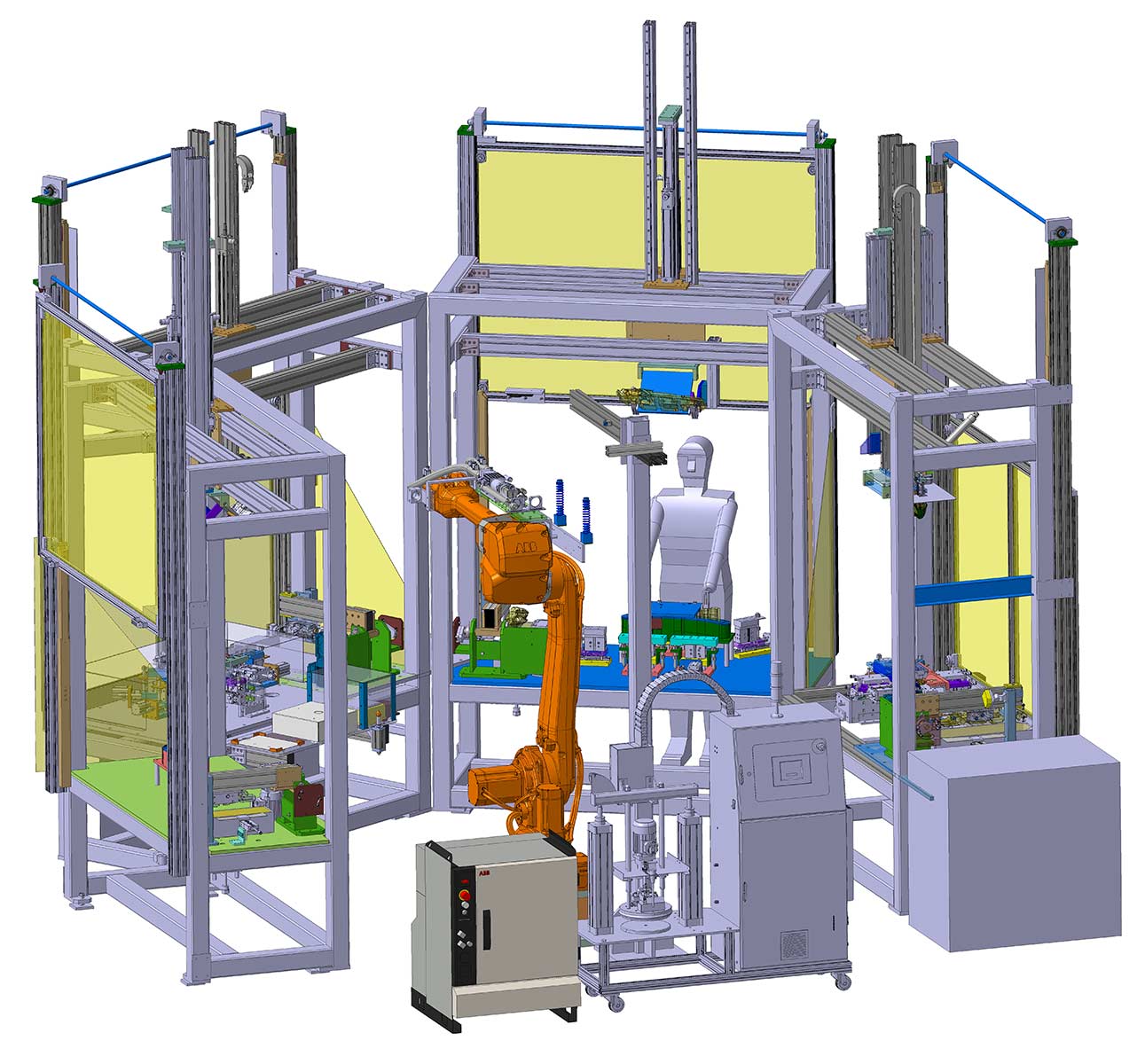

AKE technologies is a manufacturer of fully automatic assembly lines for the production of

cell contacting systems in e-mobility. Cell contact systems (CCS) are responsible for interconnecting the individual battery cells in electric vehicles. They differ in numerous features. Depending on the vehicle design and the requirements of the OEMs, there are different arrangements of the cells according to the space available in the vehicle, a parallel or series connection is possible. The cells are assembled into single or double modules and are suitable for use in hybrid vehicles (HEV / PHEV) as well as in purely electrically powered vehicles (BEV).

AKE's production systems offer an

intelligent production concept to cover a wide variety of component variants without setup processes. Different cycle times can be implemented through scalable system concepts. Complete data acquisition and process monitoring takes place during production, which guarantees

100 percent traceability.

Image: Concept example of assembly system for cell connectorsIn the following are examples of the processes that are integrated into our assembly systems for cell connectors:

Processes

1. Automatic feeding of various individual parts

- Busbars

- Power sensors

- Temperature sensors

- Housing and carrier parts

2. Component depending pre assembly of the busbars

- Equipping taps and sensors

- Assembling

- Laser welding

- Gluing

3. Mounting of the prepared busbars in the carrier parts

4. Ultrasonic welding and hot welding

5. Depending on requirements, combination with manual assembly stations (e.g. for cable assembly) or with rework stations

6. EOL testing

- High Voltage isolation tests

- Communication testing of the sensors

7. Component marking as DMX codes and text

8. Automatic packaging in customer containers

Scope of documentation

- Batch numbers of the individual parts

- Single part tracking of safety-relevant individual parts such as HV separations

- Mounting forces and distances

- Adhesive application parameters

- Laser welding parameters

- Camera measurement results

- 2D and 3D measurement results

- Test results from electrical tests

- General information about the produced part such as individual part number, production time, product variants, and much more.

Our World of Automation | Learn more about our values and about the passion for our automation solutions in the team AKE!

Learn also more about our further production lines in the field of e-mobility:

for the treatment of handles, arm rests, seat backs or trims

On all five continents, vehicle manufacturers use our compact and modular designed lamination technology. A tried-and-tested system design. material-saving concepts, automated processes and quick-change systems for maximum possible utilization make the highly reliable and low maintenance systems and tools from AKE-technologies a benchmark in the lamination sector.

Lamination system for loading floors

System description

- Compound system for mounting and processing loading floors in the trunk

- Assembly system with integrated press system and exchangeable tools

- Production of various component variants possible

Processes

- Free insertion of fabric decor and carrier part and automatic position detection by camera systems

- Plasma treatment of the folding area of the carrier part

- Application of a hot melt adhesive by means of a roller system

- Heating of the adhesive by an infrared heating field

- Laminating and edgefolding process integrated in exchangeable tools

Gluing-Laminating-System for center armrests

System description

- Bonding of the fabric decoration instead of a complicated stapling process

- Inserting and positioning of the leather decor by the worker with the help of positioning aids

- Integrated plasma pretreatment

- Fully automatic gluing and edge folding

- Additional gluing of a cover

- Integrated adhesive application for gluing, laminating and edge folding processes

- Re-work-free edge folding

- Removable tool

Lamination system with edgefolding process

System description

- Flexible system concept with four separate lamination edge-folding stations

- Variable deployment of workers (up to 4 persons)

- Workplace protection through vertical roller door systems to exclude unintentional process interruptions by the workers

- Manual equipping of the arm rest base carrier on the upper tools of the press systems

- Manual placing of the spacer fabrics with insert templates in the foam bed

- Manual placing of the leather blanks in the laminating tool with positioning of the stitching by laser pointer and vacuum fixing

- Automatic adhesive application with robot system in a spinning spray process for fixing the spacer fabric and the stitching to the base carrier

- Subsequent automatic lamination process in both tool systems

- Automatic adhesive application applied as a bead for the downstream automatic edge-folding process

- Circulating rework-free edge-folding process of the component edge

- Separate monitoring of the adhesive equipment with cyclical checking of the output and tool alignment

Our World of Automation | Learn more about our values and about the passion for our automation solutions in the team AKE!

for surface changing of arm rests, handles or trims

Dry anti-friction films open a range of possible applications for which we – together with customers and partners – always find the perfect solution. Anti-friction coatings are increasingly gaining in importance as a reliable design element. With its high degree of know-how in material comparability, AKE-technologies ensures the reduction of friction and wear, cleanliness and long service life.

System description

- Efficient coating of the parts by preventing overspray

- Reproducible, process-optimized coating process with fully-automatic robot control

- Quality certification by cleaning station and flow control

- Drying of painted parts by energy-efficient circulating air system

- Replaces cost-intensive manual gluing-on of felt strips or similar materials

- Huge savings potential in the parts price calculation for acquisition activities

For the surface treatment of instrument panels, center consols and trims

AKE-technologies has further developed flame treat technology in order to increase the surface tension of various thermoplastic materials, hence improving their adhesion. Space-saving designs and the intelligent control of all parameters minimize throughput times and costs. We place special value on safety during the flame treatment process. Consequently, all processes are seamlessly monitored and documented.

System description

- Flexible system concept with two separate flame treatment stations

- Manual equipping and removal of the base carrier for the instrument panel

- Automatic flame treatment of lamination surfaces for optimizing the adhesive adhesion with a robot system

- Tandem flame treatment tool with line and spot nozzles for optimum processing of the various surface geometries

- Quick-change component mounts

Our World of Automation | Learn more about our values and about the passion for our automation solutions in the team AKE!

+49(0)851-95584-0

+49(0)851-95584-0

General Information

General Information General Information

General Information