AKE technologies represents the system partner in the field of assembly of e-mobility components for its customers. We offer our customers experience in the development and manufacture of

assembly-testing lines for complete battery systems in various degrees of automation, from the prototype line to fully automated series production. We advise our customers on automation, manufacturing processes, security concepts and much more, always taking their individual requirements into account!

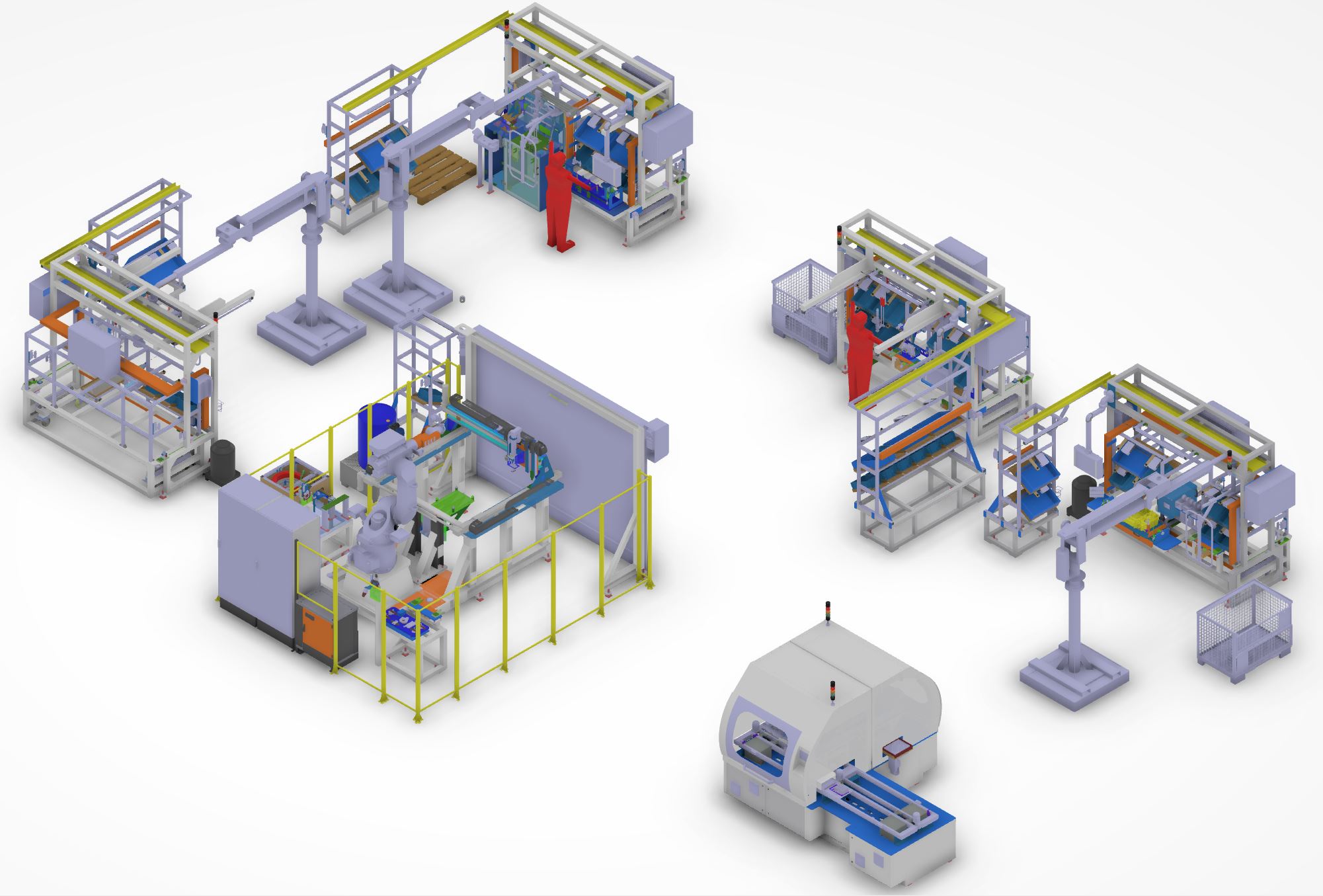

Pre-series line for the assembly of battery modules | Combination of manual and automatic processing stations

General Information

- Combination of manual and, if necessary, automatic processing stations

- Flexible design thanks to intelligent processing modules

- Integration of set-up carts and exchangeable processing modules

- Extension and reduction of the number of modules in the event of changes in the number of units

- Complete data documentation and process monitoring

Processes

- Automatic feeding and start of line tests of single cells and cell modules in different variants round cells, prismatic cells, pouch cells, modules with prismatic or pouch cells)

- Plasma or laser cleaning of battery cells and pre-treatment of application surfaces: plasma, flame, laser, liquid, ...

- Assembling of the cells with monitoring of mounting force and distance

- Application of adhesives and gap fillers including process control with camera and 3D scanning systems

- Laser welding of contacts with process monitoring

- Scope of assembly in the HV state of the battery in special HV cells (interconnection of modules, HV tests, covering of open contact points)

- Leakage test of the fully assembled system (air, helium, if necessary subsequent filling of the battery with a cooling medium)

- End of Line testing (communication test, plausibility test, high voltage test, functional test)

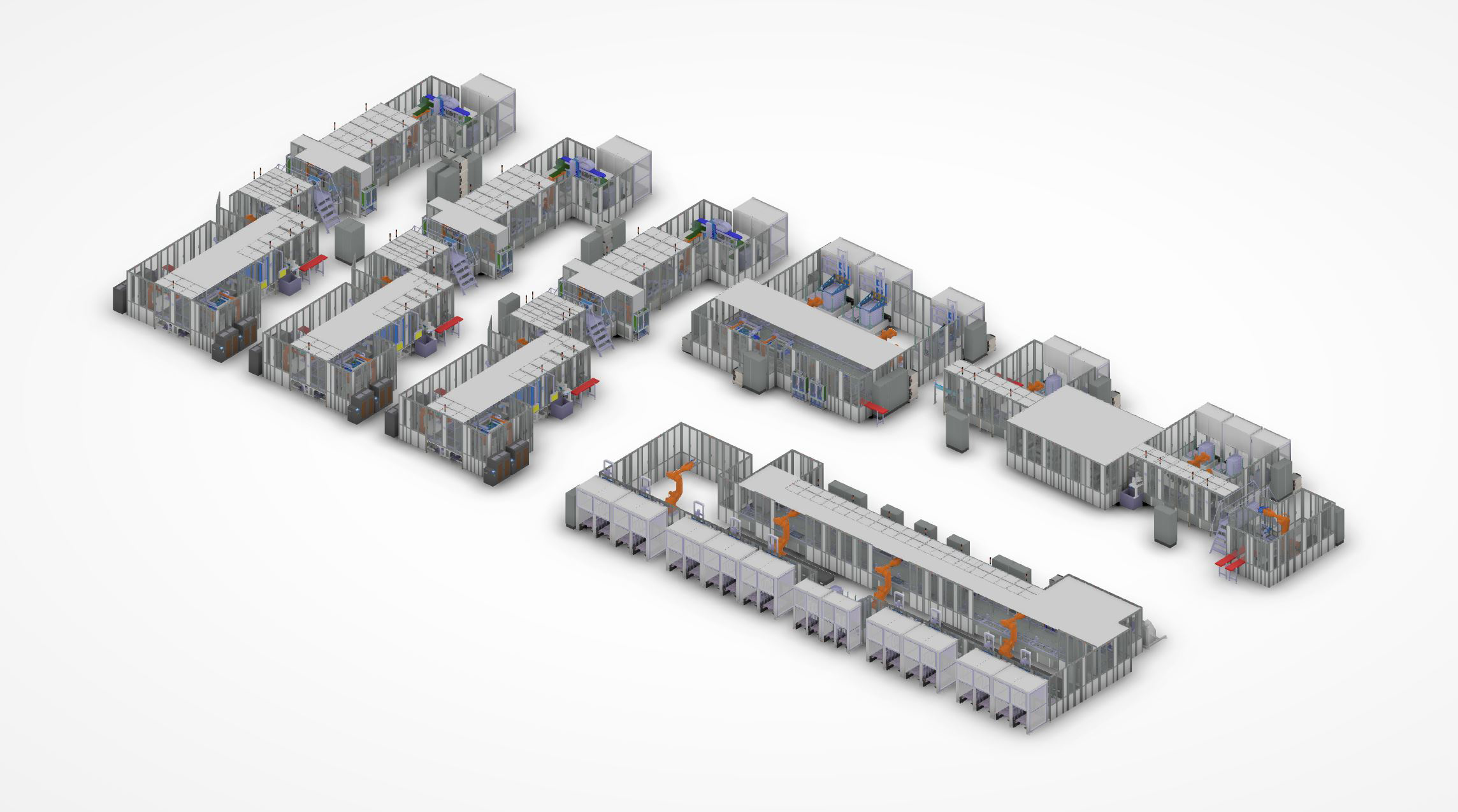

Automated assembly line for the production of battery modules from prismatic cells

General Information

- Processing of several cell variants on one line

- High demands on variant management

- Innovative transport systems for flexible plant design

- Combination of numerous individual processes in the smallest possible space

- Integrated emergency concepts in all process steps

- Process monitoring and data transfer to a higher-level production control system ensuring 100 percent traceability

Processes

- Begin of line testing to ensure processing of high quality components

- Cleaning and preparation processes on the cells, side and end plates (laser or plasma treatment, foil applications, camera inspections)

- Stacking & welding processes for battery assembly

- Pre-assembly and integration of the cell contacting system

- End of line testing (insulation and breakdown tests, cell temperature, voltage values)

- Component marking for traceability

- Automatic component output and packaging of modules

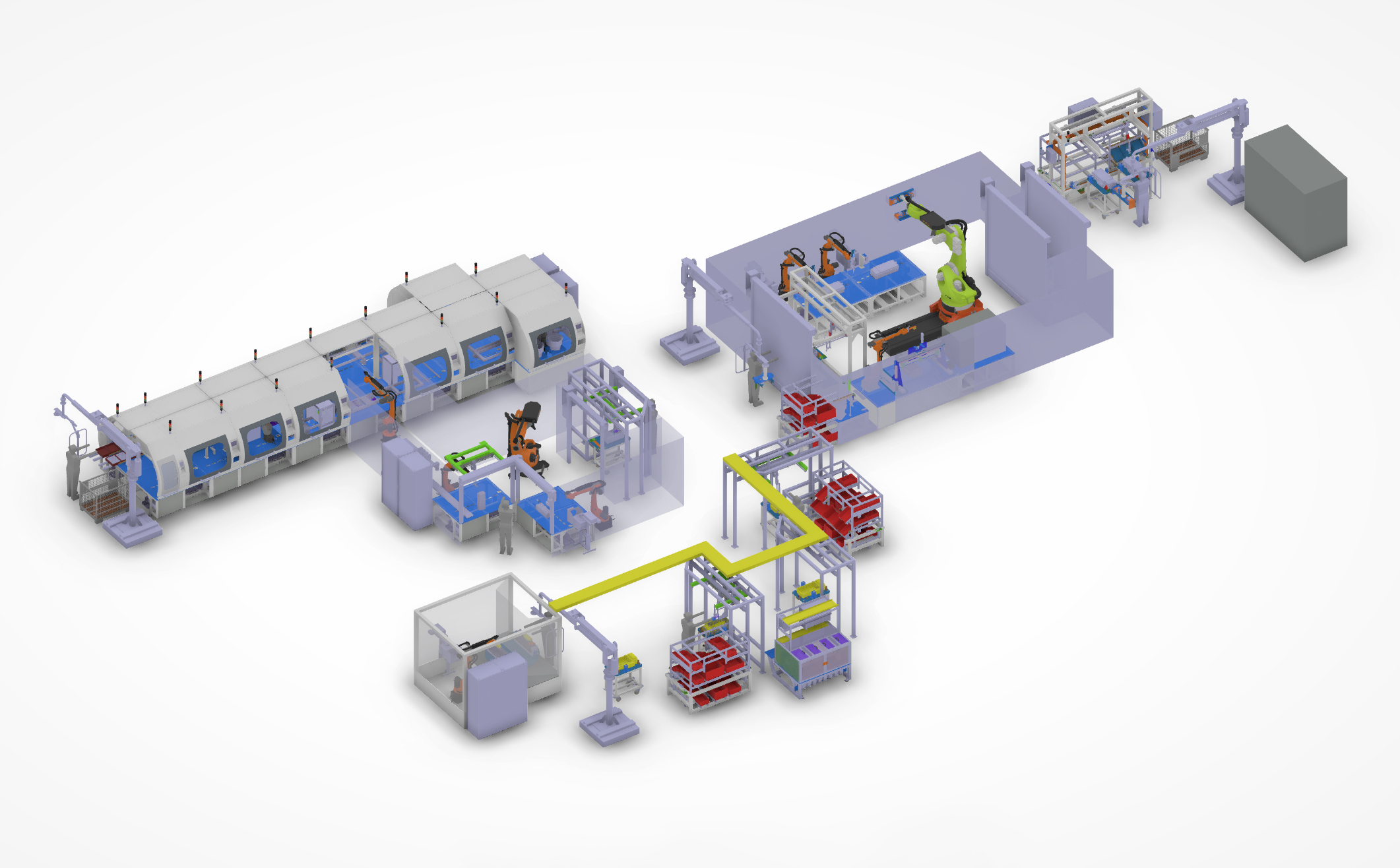

Assembly line for the production of battery modules and pack production from round cells

General Information

- Automated assembly processes with integration of manual processing steps

- Pre-production of different module variants

- Intermediate electrical testing

- Flexible pre-assembly of battery packs

- Automated final assembly area for inserting the battery modules and carrying out the HV activities

- Possibility for later integration of an automated transport system into the manual pre-assembly

- Complete data acquisition and process monitoring

Processes

- Automatic feeding and processing of single cells (cell scan, testing, cleaning)

- Assembly of single cells to battery modules (joining, laser welding, intermediate electrical testing)

- Partially automated pre-assembly of battery cases and lids (combination of manual assembly and automatic screwing stations)

- Automatic joining of modules into pre-assembled trays

- High-voltage interconnection of the battery system

- Lid assembly and leak test

- Intermediate and end of line electrical testing

- Manual component marking and packaging

Our World of Automation | Learn more about our values and about the passion for our automation solutions in the team AKE!

Learn also more about our further production lines in the field of e-mobility:

General Information

General Information General Information

General Information