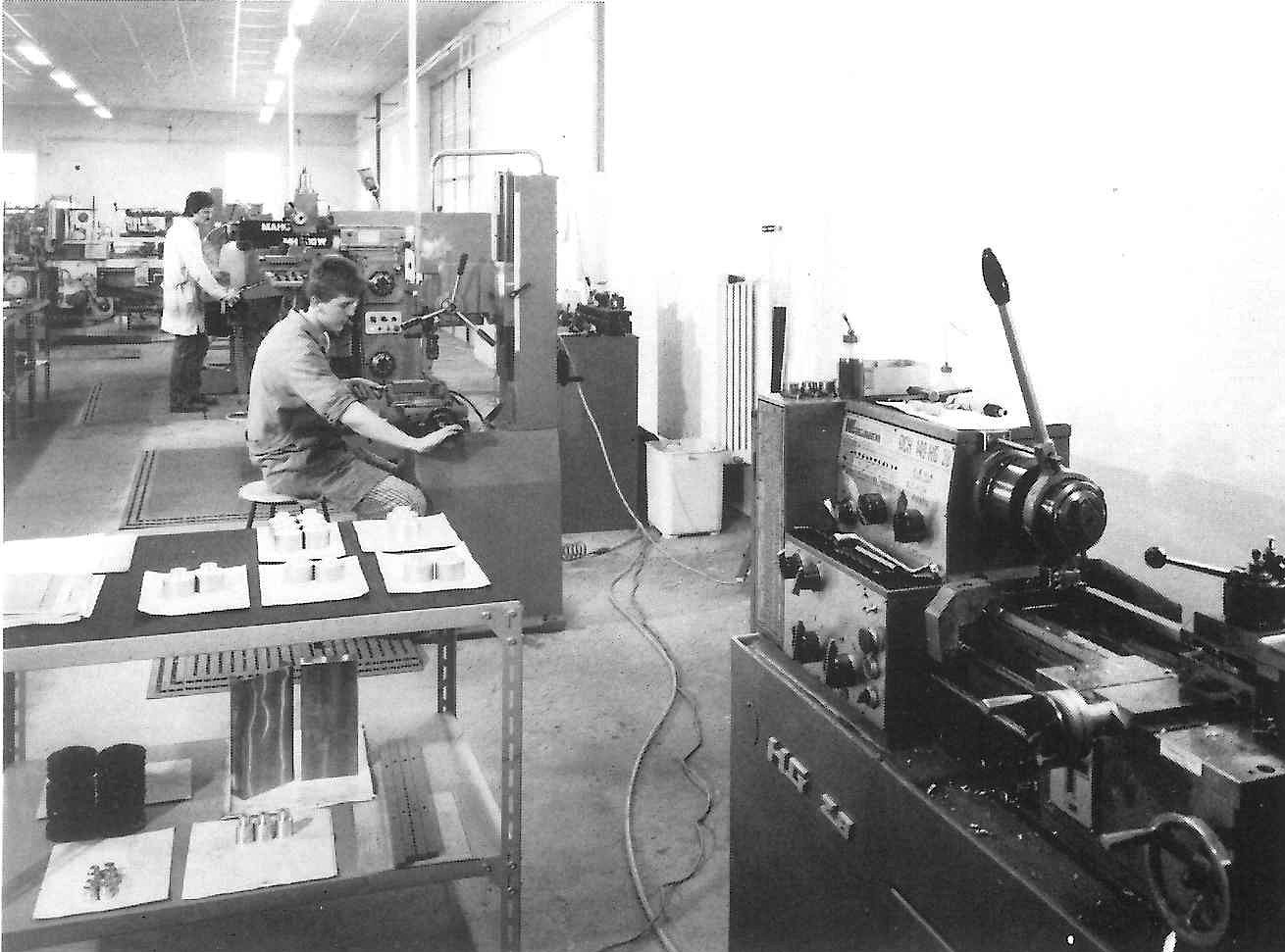

Our manufacturing then: conventional machines, one-shift operation and a lot of manual skills

Decades ago, six employees - at that time still working in one-shift operation - used conventional machines and mostly manufactured simpler components, for which mainly manual skills were of great importance.The MAHO MH 500 W represented a decisive change in our production - the first CNC milling machine from AKE which we installed in 1987.

Some time later, in 2002, the first CNC machine with an integrated tool changer was used. From this moment on it was possible to program free-form surfaces (CAM programming).

Our manufacturing today: CNC machines, CAM software and necessary IT experience

Our manufacturing today: CNC machines, CAM software and necessary IT experience

A lot has happened since then: nowadays our manufacturing comprises 25 employees who work in a two-shift operation. For many years, the advanced CNC technology has enabled AKE to manufacture more complex components and to implement free-form surfaces without any problems.Instead of the manual skills of the past - with regard to new technologies - much more control and PC knowledge slipped into the foreground, since the majority of our programs are based on CAM software (computer-aided manufacturing). This type of production enables AKE to achieve both higher quality and constant repeat accuracy.

„Manufacturing with CNC machines nowadays has become very demanding. The components are becoming more complex and compact. There is always something new to learn!" With these words, AKE manufacturing manager Herbert Wolf rounded off our conversation and looks motivated into a future full of technical developments.